Discover our Product Range

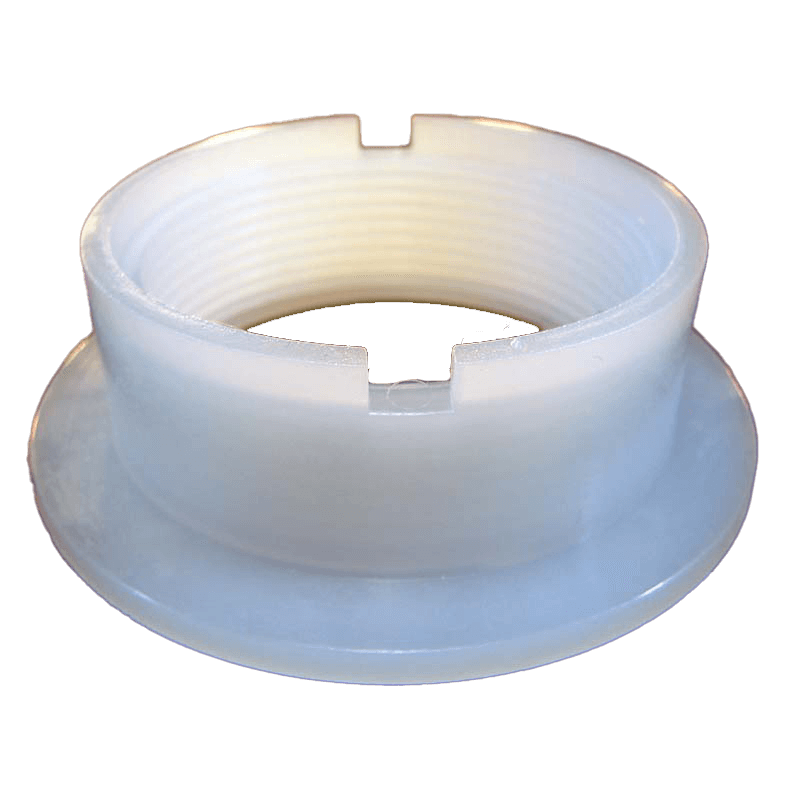

Matrix Polymers has a range of products whether its granules, powders, or special effect materials for rotomoulding applications. Check out our range of essential ancillary products.

Polyethylene

The main material of choice for the rotomoulding market and is suitable for a wide range of applications from toys to tanks. Our range of general purpose, tank and high performance polyethylene grades have been designed specifically with rotomoulding in mind, ensuring a wide processing window and the highest quality finish for your design.